Yakazara Automatic Concrete Block Production Line

——Tamisa——

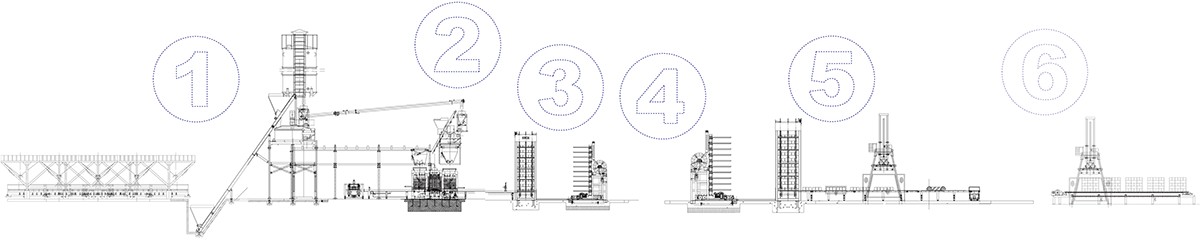

Yakazara otomatiki mutsara: vhiri loader inoisa akasiyana aggregates muBatching Station, inovayera kune huremu hunodiwa uye wozobatanidza ne simenti kubva simenti silo. Zvese zvezvishandiso zvinozotumirwa kune musanganiswa. Mushure mekusanganiswa zvakaenzana, bhandi rinotakura rinoendesa zvinhu kuBlock Kugadzira Machine. Iwo mabhuroki apedzwa achaendeswa kune otomatiki Elevator. Ipapo mota yemunwe ichatora mapallet ese emabhuraki kukamuri yekurapa kuti arapwe. Mota yemunwe inotora mamwe mabhuraki akaporeswa kuenda kuOtomatiki Lowerator. Uye pallet tumbler inogona kubvisa mapallets rimwe nerimwe uye otomatiki cuber inozotora zvidhinha ichiturika pamurwi, ipapo forogo clamp inogona kutora zvidhinha zvakapedzwa kuenda kuchivanze kunotengeswa.

——Chikamu——

1 Batching uye Kusanganisa Plant

Iyo batching uye yekusanganisa sisitimu ine yakawanda-chikamu batching chiteshi iyo inoyera otomatiki uye inoendesa iyo yakaunganidzwa kune inomanikidzirwa musanganisi. Simende inotakurwa kubva kusimende silo uchishandisa screw conveyor uye inoyerwa otomatiki pamusanganisi. Kana musanganisi apedza kutenderera kwayo kongiri inozotakurwa uchishandisa yedu pamusoro skip system kuenda kune yakazara otomatiki block muchina system.

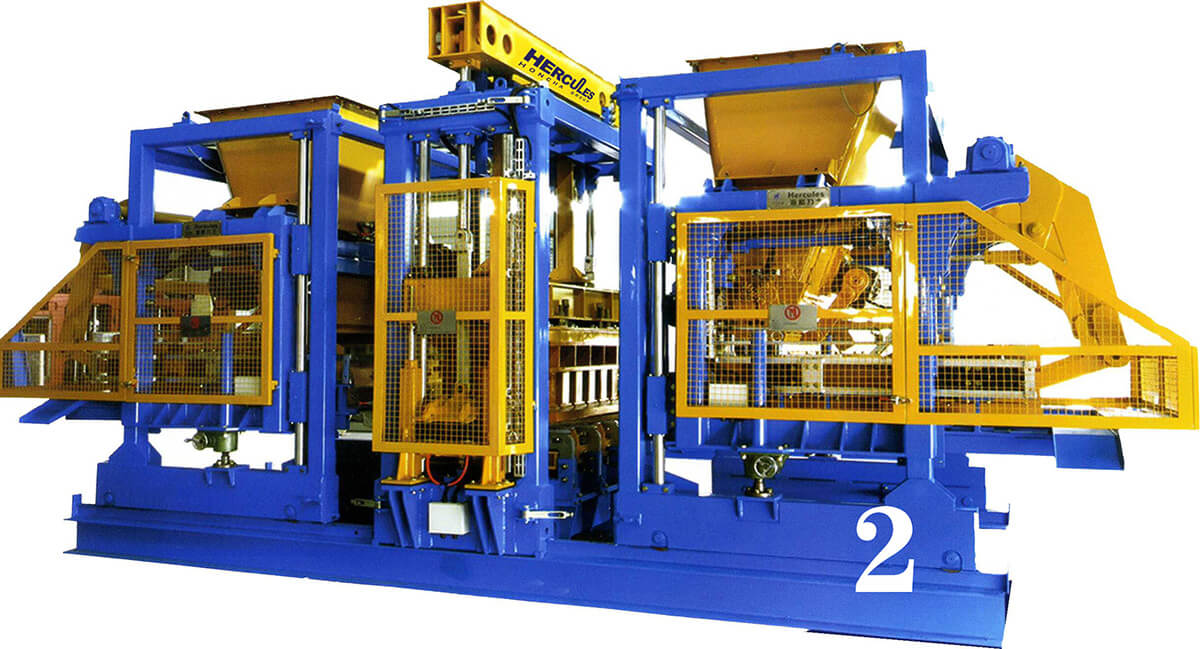

2、Block muchina

Kongiri inosundirwa panzvimbo nebhokisi rekudyisa uye inopararira zvakaenzanirana muchikamu chepasi chemukadzi. Iyo yepamusoro yechirume mold inozopinzwa muzasi mold uye kushandiswa kwakawiriraniswa tafura vibration kubva kune ese maviri mold kuti igadzikane kongiri mune yaunoda block. Muchina uyu unogona kuve wakazara otomatiki kumeso musanganiswa chikamu chakawedzerwa kubvumidza kugadzirwa kwemavara pavers.

Optional block machine modhi: Hercules M, Hercules L, Hercules XL.

3、Pallet Elevator

Mabhuroko matsva anocheneswa kuti ave nechokwadi chekuti ese akaenzana kureba uye obva atakurwa kuenda kune elevator system. Inogona kugadzirwa kuva kubva pamapfumbamwe kusvika gumi nemaviri mazinga akakwira aine mapaleti maviri padanho reshenjere kana simbi inotakura ine mabhuroko matsva.

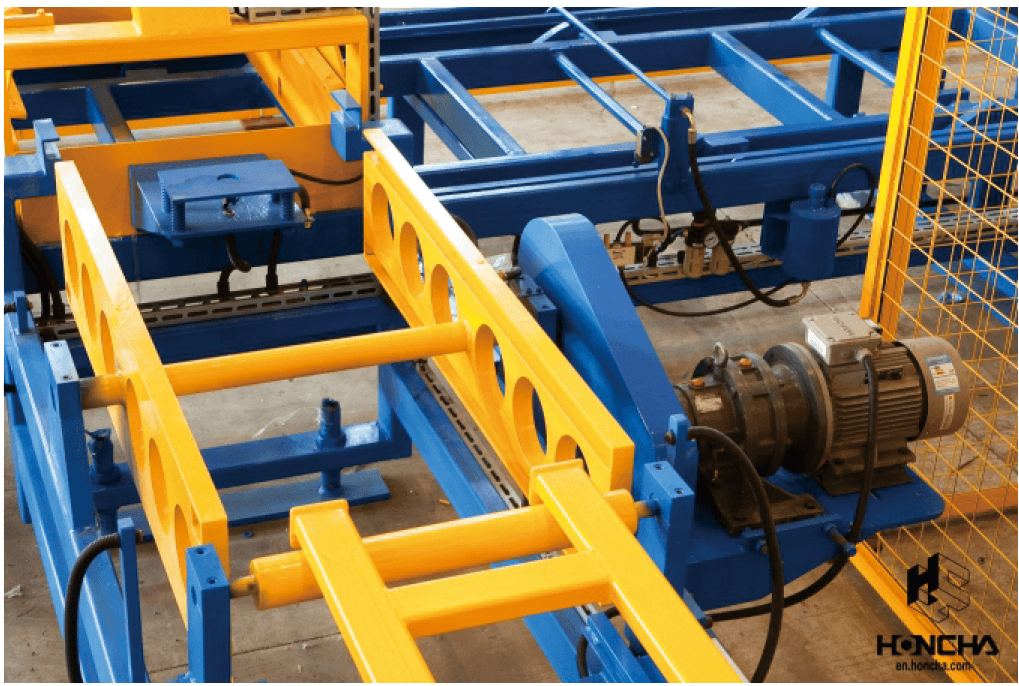

4, Finger Car System (Amai neMwanakomana Mota)

Iyo yemunwe mota sisitimu yakavakirwa kune yakaenzana nhamba yematanho seyekusimudza system uye yakagadzirirwa kutsungirira kuomarara kwekuburitsa max ekukwirisa ezvivharo kana mapavha. Ichatakura nekuturunura zvinotakura mukamuri yekurapa kwenguva yakatemerwa zvichienderana nemafekitori enzvimbo. Mabhuroki acho achaburutswa otakurwa achiendeswa kune yakaderera.

5, Pallet Lowerrator

Kana mapallets anyatso kurodha muzasi nhanho yega yega inoturunurwa kune iyo pallet yekudzoka system uye yakarongedzwa yakagadzirira cubing system.

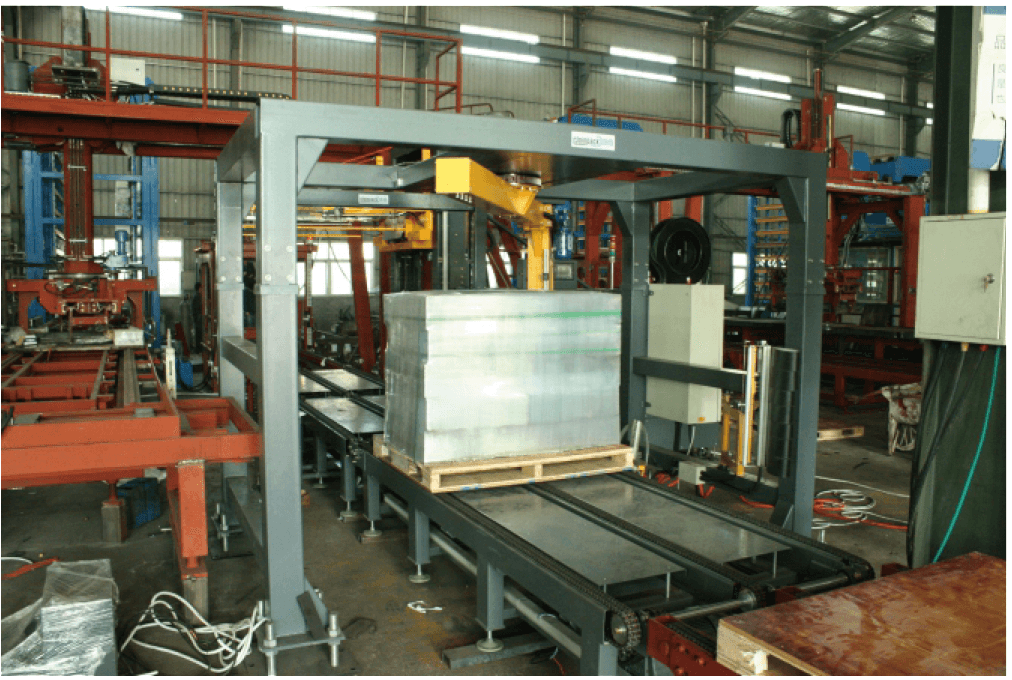

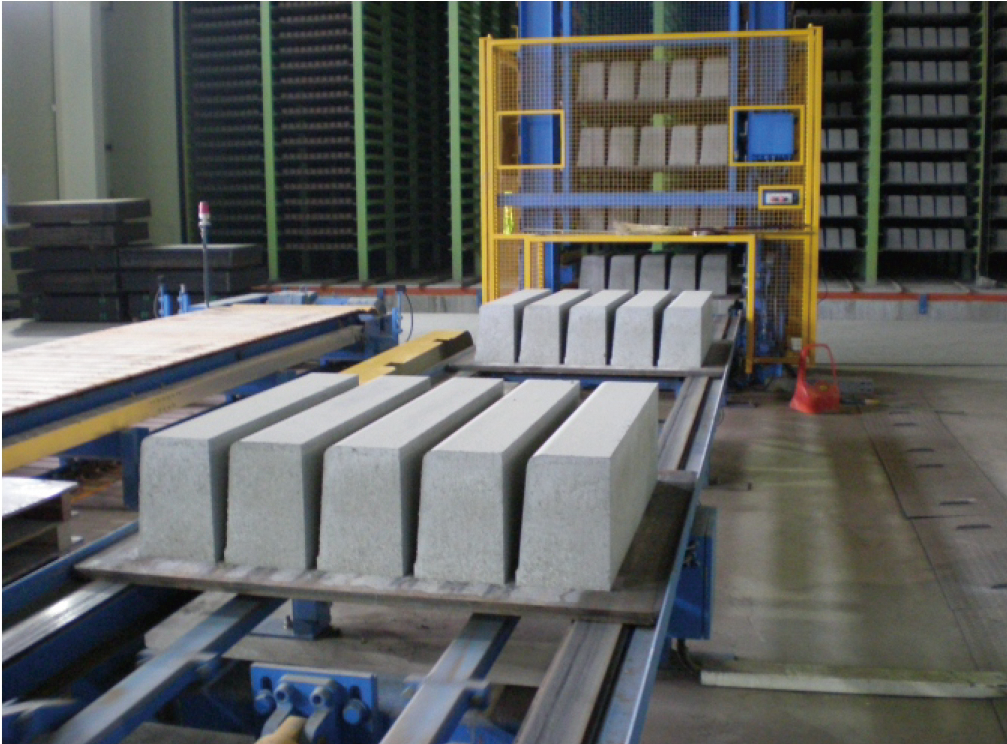

6, otomatiki Gantry Type Block Cubing System

Iyo cubing system inounganidza zvidhinha kana mapeji kubva pamapallet maviri panguva uye woyambutsa iwo pane yekubuda nayo. Iyo inoshongedzerwa neina rabha yakavharwa yekusunga maoko uye hydraulically inoshanda ne 360 dhigirii yakatwasuka kufamba.

——Full Automatic Production Line——

| Yakazara Automatic Concrete Block Production Line: Zvinhu | ||

| 1Automatic Batching Station | 2Inomanikidzwa Mixer | 3Cement Silo |

| 4Screw Conveyor | 5Cement Scale | 6Bhandi Conveyor |

| 7Pallets Conveying System | 8Concrete Block Machine | 9Blocks Conveying System |

| 10Block Sweeper | 11Elevator | 12Lowerator |

| 13Pallet Tumbler | 14Automatic Gantry Type Cuber | 15Finger Car System |

| 16Central Control Room | 17Hydraulic Station | 18Wheel Loader |

| 19Fork lift | 20Curing Chamber | |

Kupeta muchina

Pallet tendeuka

Imba yekugeza

Dry side

—— Production Capacity——

★Mamwe masaizi ezvidhinha asina kutaurwa anogona kupa madhirowa kubvunza nezve chaiyo kugadzirwa kwesimba.

| Kukwanisa kugadzira | ||||||

| Hercules M | Mabhodhi ekugadzira: 1400 * 900 Nzvimbo Yekugadzira: 1300 * 850 Stone Height: 40 ~ 500mm | |||||

| Proudct | Saizi(mm) | Face mix | Pcs/cycle | Cycles/min | Kugadzirwa/8h | Kugadzira cubic m/8h |

| Standard Brick | 240×115×53 | X | 60 | 4 | 115,200 | 169 |

| Hollow block | 400*200*200 | X | 12 | 3.5 | 20,160 | 322 |

| Hollow block | 390×190×190 | X | 12 | 3.5 | 20,160 | 284 |

| Hollow Brick | 240×115×90 | X | 30 | 3.5 | 50,400 | 125 |

| Paver | 225×112.5×60 | X | 30 | 4 | 57,600 | 87 |

| Paver | 200*100*60 | X | 42 | 4 | 80,640 | 97 |

| Paver | 200*100*60 | O | 42 | 3.5 | 70,560 | 85 |

| Hercules L | Mabhodhi ekugadzira: 1400 * 1100 Nzvimbo Yekugadzira: 1300 * 1050 Stone Height: 40 ~ 500mm | |||||

| Proudct | Saizi(mm) | Face mix | Pcs/cycle | Cycles/min | Kugadzirwa/8h | Kugadzira cubic m/8h |

| Standard Brick | 240×115×53 | X | 80 | 4 | 153,600 | 225 |

| Hollow block | 400*200*200 | X | 15 | 3.5 | 25,200 | 403 |

| Hollow block | 390×190×190 | X | 15 | 4 | 14,400 | 203 |

| Hollow Brick | 240×115×90 | X | 40 | 4 | 76,800 | 191 |

| Paver | 225×112.5×60 | X | 40 | 4 | 76,800 | 116 |

| Paver | 200*100*60 | X | 54 | 4 | 103,680 | 124 |

| Paver | 200*100*60 | O | 54 | 3.5 | 90,720 | 109 |

| Hercules XL | Mabhodhi ekugadzira: 1400 * 1400 Nzvimbo Yekugadzira: 1300 * 1350 Stone Height: 40 ~ 500mm | |||||

| Proudct | Saizi(mm) | Face mix | Pcs/cycle | Cycles/min | Kugadzirwa/8h | Kugadzira cubic m/8h |

| Standard Brick | 240×115×53 | X | 115 | 4 | 220,800 | 323 |

| Hollow block | 400*200*200 | X | 18 | 3.5 | 30,240 | 484 |

| Hollow block | 390×190×190 | X | 18 | 4 | 34,560 | 487 |

| Hollow Brick | 240×115×90 | X | 50 | 4 | 96,000 | 239 |

| Paver | 225×112.5×60 | X | 50 | 4 | 96,000 | 146 |

| Paver | 200*100*60 | X | 60 | 4 | 115,200 | 138 |

| Paver | 200*100*60 | O | 60 | 3.5 | 100,800 | 121 |

+86-13599204288

+86-13599204288