Palletizerchishandiso cheotomatiki chinoshandiswa zvakanyanya mumunda wekugadzira maindasitiri, kunyanya mukutakura uye logistics link. Inonyanya kushandiswa kurongedza zvakatsetseka zvigadzirwa zvakagadzirwa, senge mabhegi, mabhokisi, uye zvinhu zvemumagaba, pamapallet, skids, kana zvimwe zvinotakura mune imwe hurongwa hwekurongeka uye maseru kuti aumbe yakagadzika stack chimiro, kuitira kufambisa mabasa anotevera sekuchengetera, kutakura, kurodha nekuburitsa.

Panyaya yemaitiro uye anoshanda modules, apalletizerkazhinji inosanganisira zvikamu zvakakosha senge dhizaini yekufambisa, yekubata uye yekuisa mudziyo, yekudzora system, uye furemu. Iyo yekufambisa sisitimu ine basa rekuendesa zvinhu kuti zvipinzwe palletizer kunzvimbo yekushanda ye palletizer nenzira yakarongeka, kuve nechokwadi chekuti zvinhu zvinokwanisa kusvika nemazvo panzvimbo yakatarwa uye kugadzirira kunotevera kubata mabasa. Iyo yekubata uye yekuisa mudziyo ndiyo yakakosha chikamu cheiyo palletizer. Inogona kutora nzira dzakasiyana dzekubata, senge mechanic grippers, vacuum suction cups, clamping masisitimu, nezvimwewo, zvinoenderana nechimiro, saizi uye huremu hwezvinhu zvakasiyana, kunyatsobata zvinhu uye nekuzviisa mushe kune dzinoenderana zvinzvimbo zvinoenderana ne preset stacking mode, kuitira kuti uone kurongeka kwezvinhu. Iyo control system ndiyo "uropi" hwepalletizer. Iyo inonyatso kudzora iyo yese palletizing maitiro kuburikidza neakavakirwa-mukati zvirongwa uye algorithms, kusanganisira kumhanya kumhanya kweyekufambisa sisitimu, kutevedzana kwekuita kwechishandiso chekubata, chinzvimbo uye mitsara yekuturika, nezvimwewo, kuve nechokwadi che automation uye kugona kweiyo palletizing maitiro. Iyo furemu inopa yakagadzika rutsigiro chimiro chechikamu chimwe nechimwe che palletizer, kuve nechokwadi kugadzikana uye kuvimbika kwemidziyo panguva yekushanda.

Panyaya yekufambiswa kwebasa, kana zvinhu zvinofanirwa kuiswa palletized zvinopinda mukushanda kwepalletizer kuburikidza nekutakura sisitimu, iyo control system inotumira mirairo kune yekubata uye yekuisa mudziyo zvinoenderana neyakagadzikwa parameter uye ikozvino kushanda mamiriro. Mudziyo wekubata unobata nekukurumidza, unobata zvinhu nenzira kwayo, uye wobva waendesa zvinhu kunzvimbo yakatarwa pamusoro pepallet maererano neyakarongwa nzira yekuisa uye inozviisa pasi zvishoma nezvishoma kuti ipedze kurongedza kweimwe layer yezvinhu. Mushure meizvozvo, sisitimu yekufambisa inoenderera mberi nekuendesa batch rinotevera rezvinhu, uye mudziyo wekubata unodzokorora zviito zviri pamusoro kurongedza rinotevera. Kutenderera uku kunoenderera mberi kusvika pallet yaiswa kune yakatemerwa nhamba yezvikamu kuti iite yakazara stack. Iyo pallet iyo yapedza kurongedza ichatakurwa kubva kunzvimbo yekushanda ye palletizer neiyo yekufambisa sisitimu uye kupinda muwarehousing kana chekufambisa chinongedzo.

Palletizersvane zvakawanda zvakakosha zvakanakira. Kutanga kushanda zvakanaka. Inogona kuenderera mberi ichiita mashandiro epalletizing nekukurumidza, iyo inovandudza zvakanyanya kushanda kwekugadzira kana ichienzaniswa neyemanyorero palletizing uye inokwanisa kusangana nekushanda kwakanaka kwekuda kwemabhizinesi makuru ekugadzira. Chechipiri kururama. Kuburikidza neiyo chaiyo yekudzora sisitimu uye magadzirirwo emuchina, iyo palletizer inogona kuve nechokwadi chekuti chinhu chimwe nechimwe chakanyatsoiswa munzvimbo yakafanotemerwa, uye chimiro chakaturikidzana chakachena uye chakagadzikana, kudzivirira matambudziko akadai sekusarongeka uye hunhu hunogona kuitika mumanyorero palletizing, izvo zvinokonzeresa kuchengetedzwa kwekuchengetedza zvinhu uye kutakura. Chechitatu kugadzikana. Iyo palletizer inogona kumhanya yakadzikama kwenguva yakareba uye haisi nyore kukanganiswa nezvinhu zvakaita sekuneta kwevashandi uye manzwiro, ayo anogona kuve nechokwadi chekuenderera uye kugadzikana kwemaitiro ekugadzira uye kugadzirisa danho rekugadzira remabhizinesi. Pamusoro pezvo, maererano nekusimba kwevashandi uye mutengo, kushandiswa kwepalletizers kunoderedza zvakanyanya kuwanda kwevashandi uye kunoderedza kuvimba kwebhizinesi pabasa. Kunyanya mune mamwe mamiriro epalletizing ane kusimba kwekushanda kwakanyanya uye hutsinye hwekushanda nharaunda (senge tembiricha yakakwira, tembiricha yakaderera, guruva, ruzha, nezvimwewo), haingovimbise hutano hwevashandi chete asiwo inogona kuderedza mutengo wevashandi kusvika pamwero wakati.

Nekuenderera mberi kwekuvandudzwa kwemaindasitiri otomatiki tekinoroji, palletizers zvakare anoramba achikwidziridzwa uye kudzokororwa. Mapalletizer emazuva ano anowedzera kubatanidza matekinoroji epamberi senge hungwaru hwekugadzira uye kuona muchina. Iko kushandiswa kwemuchina wekuona tekinoroji inogonesa ma palletizer kuti aone chimiro, ruvara, chinzvimbo uye rumwe ruzivo rwezvinhu munguva chaiyo kuburikidza nekuona ma sensors semakamera, zvichiwedzera kuvandudza iko kwekubata nekuisa. Kunyangwe paine kutsauswa kwechinzvimbo panguva yekufambisa, inogona kugadziriswa uye kubhadharwa. Artificial intelligence tekinoroji inogona kugonesa palletizers kuve neimwe yekudzidza uye optimization kugona, otomatiki kugadzirisa iyo stacking zano zvinoenderana neakasiyana ekugadzira mabasa uye hunhu hwechinhu, uye kuona hungwaru uye hunoshanda palletizing mashandiro.

Muchidimbu, seimwe yemidziyo yakakosha yemaindasitiri otomatiki, palletizers anoita basa risingadzokerike mukugadzirwa kwemazuva ano kwemaindasitiri. Ivo havangonatsiridza kugona kwekugadzira uye kunaka kwechigadzirwa chemabhizinesi asi zvakare vanosimudzira otomatiki uye nehungwaru kusimudzira kwese kwekugadzira maitiro, vachipa rutsigiro rwakasimba rwekudzikisa mutengo wemabhizinesi, kuwedzera kwehunyanzvi uye kusimudzira kwakasimba.

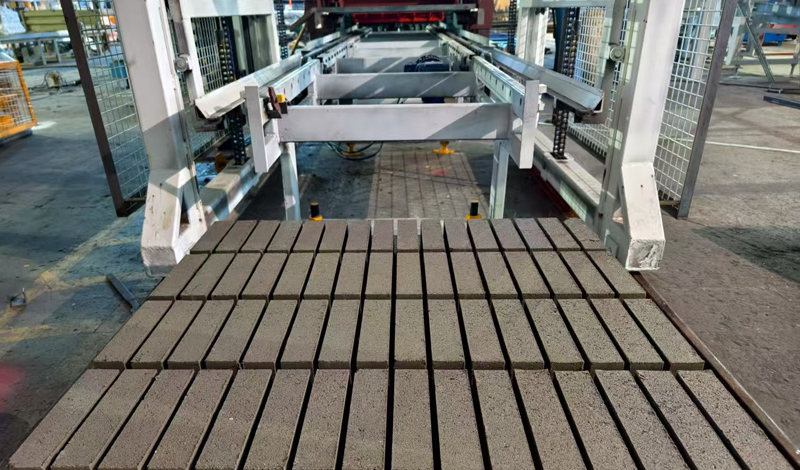

Muchina uri pamufananidzo ndewepalletizer.

Iyo palletizer yakakosha otomatiki michina mukugadzirwa kwemaindasitiri, kunyanya muminda yekurongedza uye zvinhu. Inonyanya kushandiswa kurongedza zvakachena zvigadzirwa zvakaita semabhegi, mabhokisi, uye emumagaba pazvitakuri semapallet mune yakarongeka uye mitsara yekugadzira yakagadzikana stack chimiro, kufambisa kunotevera kuchengetwa, kutakura, kurodha uye kurodha.

Panyaya yechimiro, palletizer ine zvikamu zvakaita seyekufambisa sisitimu, yekubata uye yekuisa mudziyo, yekudzora system, uye furemu. Iyo yekufambisa sisitimu yakarongeka inotumira zvinhu kuti zvipinzwe pallet munzvimbo yekushanda; iyo yekubata uye yekuisa mudziyo ndiyo musimboti, unogona kunyatsobata zvinhu kuburikidza ne mechanical grippers, vacuum suction cups, etc. maererano nechimiro chezvinhu uye zviise maererano ne preset mode; iyo yekudzora sisitimu, se "uropi", inonyatso kudzora kumhanya kwekufambisa, kubata kutevedzana, kurongedza chinzvimbo uye zvidimbu kuburikidza nehurongwa algorithms kuve nechokwadi che automation uye kugona; iyo furemu inopa tsigiro yakatsiga kune chimwe nechimwe chikamu.

Munguva yekushanda, zvinhu zvinofanirwa kuiswa palletized zvinopinda muchikamu chekushanda kuburikidza nehurongwa hwekufambisa, uye iyo control system inotumira mirairo kune kubata nekuisa mudziyo zvinoenderana nemaparamita uye chimiro. Mudziyo wekubata unokurumidza kubata zvinhu, wozvifambisa nenzira yakarongwa kuenda kunzvimbo yakatarwa pamusoro pepallet uye zvishoma nezvishoma unozviisa pasi kuti upedze kurongedza kweimwe layer. Mushure meizvozvo, sisitimu yekufambisa inotumira bhechi rinotevera rezvinhu, uye mudziyo wekubata unodzokorora chiito kurongedza rinotevera layer. Kutenderera kunoenderera mberi kusvika pallet yasvika kune yakatemerwa nhamba yezvikamu kuti iite yakazara stack, uye yobva yatakurwa kuenda neiyo nzira yekufambisa kupinda mudura rekuchengetedza kana chekufambisa chinongedzo.

Palletizersvane zvakakosha zvakanakira, kushanda zvakanaka, kwakaringana uye kugadzikana. Ivo vanogona kuderedza kuwanda kwevashandi uye mutengo wevashandi wemabhizinesi, uye zvakare kuve nechokwadi chekushanda munzvimbo dzakaoma. Nekuvandudzwa kwemaindasitiri otomatiki, vanosanganisa matekinoroji akadai sehungwaru hwekugadzira uye kuona kwemuchina kuti vaenderere mberi nekuvandudza humbowo nehungwaru, kubatsira mabhizinesi kuderedza mitengo, kuwedzera kushanda nesimba uye kubudirira kwakasimba.

Nguva yekutumira: Sep-05-2025

+86-13599204288

+86-13599204288